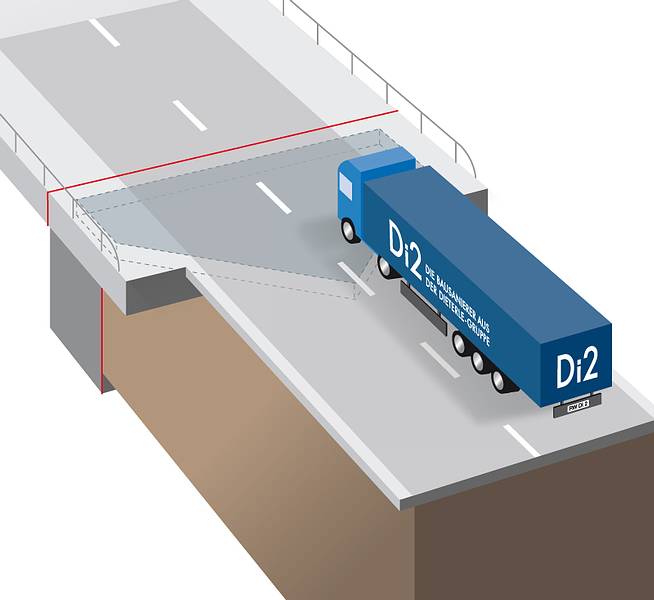

THE PROBLEM ZONE AT THE BRIDGE TRANSITION POINT

RISKS CAUSED BY SUBSIDENCE, CRACKING AND AQUAPLANING

Damage to lane transition points on road bridges incurs annual costs that run into millions and constitute a hazard to life and limb for car drivers and bike riders. This damage is caused by heavy goods traffic, which exerts extreme impact and rolling forces on the earth embankment at bridge end points – causing subsidence, cracking and severe deterioration.

This in turn causes the substrate to subside, so the asphalt layer applied to it, forming the road surface, cracks and the bridge then needs to be renovated. When subsidence occurs at the damaged transition seam, aquaplaning or black ice can caused serious road traffic accidents.

Typical damage symptoms on a bridge – this approach road was last renovated just a couple of years ago.

DAMAGE KEEPS ON RECURRING

Usually, renovation is more than a once-only operation because the conventional processes do not eliminate the actual causes but instead simply apply a new surface to that section of road. The damaged asphalt surface is planed away and the area over the transition structure is re-asphalted.

However, the compressive stresses, crushed material and subsidence in the substrate usually give rise, within just a few months, to further damage to the road surface.

The Raubach shoulder bridges the critical area between bridge and landward ends – preventing damage at these points.

SERIOUS DAMAGE CAUSED BY HEAVY-GOODS TRAFFIC

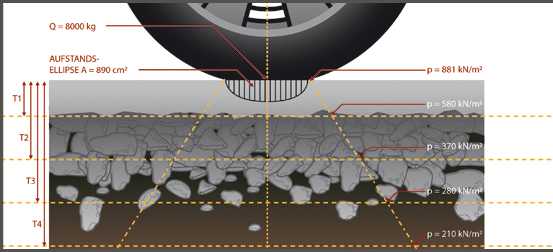

THE FORCES EXERTED GO IN DEEP

Trucks weighing many tons apply great stress to the transitional area between bridge and earth foundations. While the bridge structure itself is relatively rigid, the filling material subsides over time and the bridging asphalt layer starts to crack.

Shortly before the actual construction of a bridge commences, the substrate is subjected to increased levels of stress and load due to the absence of a static connection. That causes the construction of the road substrate to sag, leading to this typical set of damage symptoms.

FIVE GOOD ARGUMENTS IN FAVOR OF THE RAUBACHER SHOULDER

1. AQUAPLANING

Accidents caused by aquaplaning along the edges of bridges can be prevented. When road subsidence is avoided, water cannot collect, nor can ice be formed, thus preventing road users from being catapulted off a bridge.

2. RENOVATION COSTS

The Client saves a vast amount of money: Renovation of road transition points is required less frequently. The cost of maintenance drops substantially.

3. ROAD TRAFFIC DELAYS

Road traffic delays caused by bridge construction work are minimized as a consequence. Fewer gridlocks translate into reduced costs, less damage to the environment and impact on local residents.

4. BRIDGE UTILIZATION PERIOD

The Client and Contractor can scale down their provisions for repairs and warranty claims. This minimized impact in turn leads to the bridge utilization period being extended by a wide margin.

5. CONSTRUCTION DELAYS

The Raubacher shoulder is calculated and individually manufactured by our specialist structural engineering department on the basis of specific loading data and of bridge dimensions. This helps to eliminate cost-intensive construction delays.

VERGABEHINWEISE.

WICHTIGER HINWEIS ZUR VERGABE.

Aus gegebenen Anlass weisen wir auf die Bestimmungen der VOB Teil A, Ausgabe Mai 2006, §3, Absatz 4(a) hin:

Freihändige Vergabe ist zulässig, wenn die Öffentliche Ausschreibung oder Beschränkte Ausschreibung unzweckmäßig ist, besonders weil für die Leistung aus besonderen Gründen (z.B. Patentschutz, besondere Erfahrungen oder Geräte) nur ein bestimmter Unternehmer in Betracht kommt.

Unsere Bauprodukte genießen Patentschutz und gehören damit zum Stand der Technik.

Vor allem bei öffentlichen Bauprojekten sind sie vorzugsweise einzusetzen, was durch den hier zitierten Absatz der VOB unterstützt wird.